Sine-on-Random Vibration Testing

February 23, 2021

Analyzing Waveforms

Reproducing Waveforms

Fatigue Damage Spectrum (FDS)

Sine-on-Random (SoR) Test Generation

Shock Response Spectrum (SRS)

Back to: Test Development with Recorded Data

Developing a vibration test profile that represents the end-use environment is critical when evaluating product design. Many environments contain both sinusoidal and random vibration, and these mixed-mode environments require particular attention when developing an appropriate test.

For example, a product with rotational components is likely exposed to sinusoidal and random vibration. The dominant sinusoidal vibration derives from the rotating part(s), and the random vibration comes from the engine or other vibrating components.

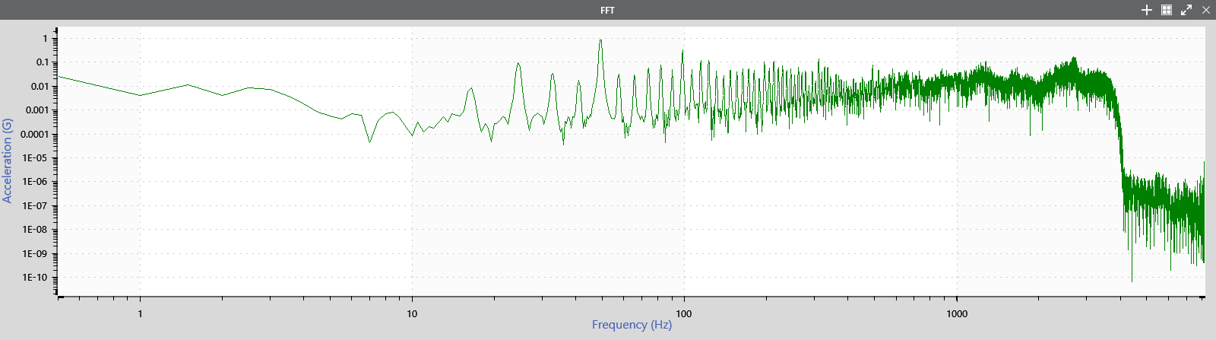

In the FFT analysis below, an engine recording shows dominant narrowband spikes that correlate to the RPM.

Initial FFT analysis of engine recording.

Both vibration types are relevant to product testing if they potentially affect performance. Therefore, a test profile representing such an environment must include both sine and random vibration.

While random tests are standard in vibration testing, they are not suitable for replicating a mixed-mode environment. Instead, engineers can develop a sine-on-random (SoR) test profile using recorded data. Below, both test methods are discussed with consideration to devices with rotating parts.

Sinusoidal Vibration and the FDS

As discussed in this course, engineers use the FDS to generate an accelerated random vibration test profile from recorded data. If an environment contains random vibration only, the FDS can use a rain flow algorithm and cycle counting to create a power spectral density (PSD) that is the damage equivalent to the original environment.

For a random-only environment, the FDS is a reliable option for creating an accelerated random test profile. Random vibration tests are representative of real-world vibration; however, a random test cannot be used to re-create the vibration of an environment with dominant sinusoidal tones.

Limitation of the FDS Algorithm

While the FDS accounts for non-Gaussian random vibration, the algorithm is not compatible with sinusoidal vibration. FDS analysis assumes input data are random. When used to replicate sinusoidal vibration, it generates random excitation at the sinusoidal frequencies, resulting in an inaccurate test profile.

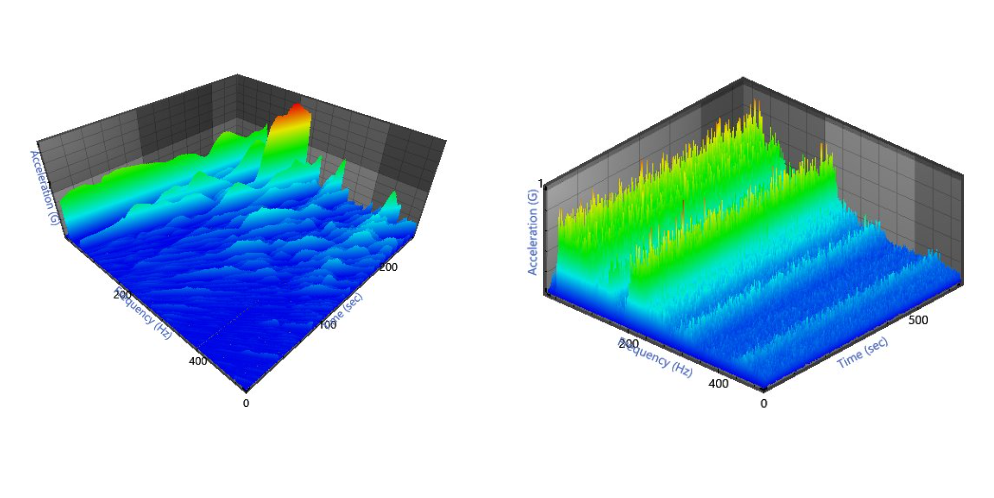

Spectrogram comparison of recorded engine vibration (left) and an FDS-generated PSD profile from the recording (right).

A test profile should represent real-world vibration as accurately as possible. If sinusoidal vibration causes a failure during early testing, then the accurate sine tones must be included in the test profile to re-create the failure. Otherwise, the test engineers will have trouble determining the cause of failure.

SoR Test Generation

SoR test generation is better suited to re-create the vibration of mixed-mode environments using recorded data. The sinusoidal and random vibration are processed separately and then combined, resulting in a mixed-mode test with sine tones superimposed on a random background.

To generate an SoR test, the correct test acceleration method must be used for both vibration types. The result is an accelerated vibration test reflective of the original environment.

Preview of STAG

The testing industry does not have a standard method of SoR test development, and the process of manually generating separate sine and random accelerated test profiles can be time-consuming and prone to error.

Vibration Research developed the Sine Tracking, Analysis and Generation (STAG) tool as an accurate and efficient option for SoR test development for products with rotating components. The next lesson walks through the SoR test development process with STAG.