Vibration Sensors

June 10, 2022

Back to: Sensors for Vibration Testing

Accurate vibration test results depend on several pieces of equipment, including the sensor. Even with a top-of-the-line controller and shaker, a system still needs to properly detect the vibration for control.

A triaxial accelerometer.

Sensors convert physical events—such as vibration—into electrical signals. The engineer attaches one or more to the device under test (DUT) or shaker table, and the sensor outputs the response to the controller.

Vibration sensors are also called transducers, although there is technically a difference; a sensor receives and responds, and a transducer converts one energy to another. However, the industry often interchanges them because transducers are sensing devices.

Types of Sensors

Sensors are classified according to the property they measure. Although accelerometers (sensors that measure acceleration) are the most common vibration sensor, a test engineer may select other sensors depending on the test type and goals. Sensors can measure force, pressure, position, and much more.

Sensor Electronics

Most sensors do not produce voltage but instead respond to external excitation. For example, the material in a piezoelectric accelerometer generates an electrical charge proportional to the excitation force. Sensors that require external excitation are active, while passive sensors self-generate an electrical output signal.

As a sensor’s output is generally low, its circuit will condition the response to provide a corresponding measurement. The Filtering/Signal Conditioning lesson will delve more into this topic.

Closed-loop Vibration Testing

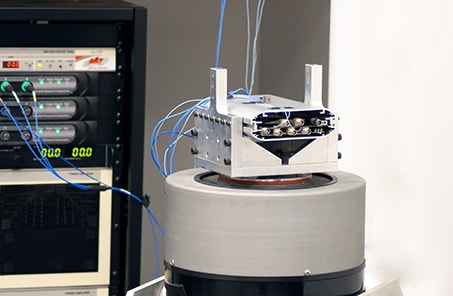

Example of a vibration shaker system setup.

During a closed-loop vibration test, the sensors are critical to vibration control. They send the response to the vibration controller, which compares it to the demand. If the response is out of tolerance, the controller adjusts the drive signal.

This process allows test engineers to control the vibration test at the desired parameters and prevents over/under-testing. Without the proper sensor, data may not be accurate or critical events may be overlooked. Therefore, it is crucial that test engineers understand this equipment and implement it correctly.