Sensors for Field Data Recording

June 10, 2022

Back to: Sensors for Vibration Testing

In addition to vibration control, vibration test engineers use sensors for data recording. Vibration data collected during field trials provide insight into reliability and performance issues. The engineer mounts the sensor(s) to areas of interest, and the sensor outputs the response signal to a data acquisition (DAQ) system. Then, the engineer can analyze the data in post-process to better understand the test item’s response, diagnose an issue, or generate a vibration control test profile.

Examples of a Recording Setup

Electric Vehicle vs. the Internal Combustion Engine

The team at Vibration Research mounted sensors to an electric vehicle and a vehicle with an internal combustion engine and drove them on the same route to gather acoustic and vibration data. The purpose was to gain a better understanding of the differences in NVH of the vehicle types.

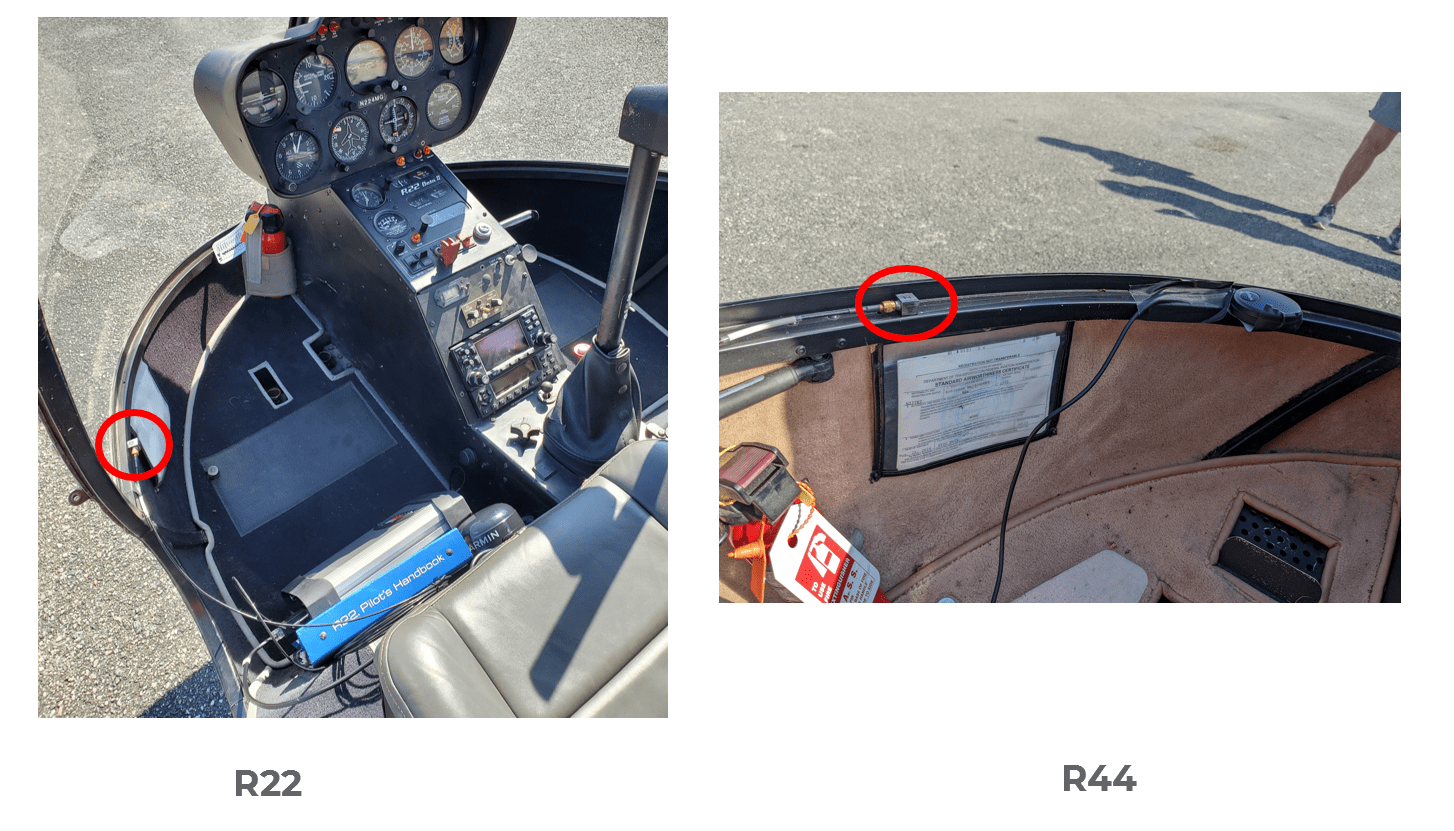

Helicopter Comparison

A VR team recorded and compared data from two helicopters of the same manufacturer: the Robinson R22 and R44. They installed an ObserVR1000 in both helicopters along with a GoPro, GPS, headset microphone, cabin microphone, and triaxial accelerometer.

View the ArticleConfiguring Sensors for Recording

Before recording, the engineer must configure the inputs. DAQ systems support anywhere from 1 to 100+ channels. The channels must be connected, enabled, and configured correctly to gather accurate data.

Configuration can be a challenge if it requires manual entry. However, some DAQ systems can read TEDS, similar to vibration controllers. For example, the ObserVR1000’s auto-TEDS feature automatically detects and configures sensors, eliminating setup errors and reducing setup time.

Triggering

As a default, most DAQ systems record all data from start to finish. However, this can lead to the collection of a mass amount of data irrelevant to an engineer’s analysis.

With the VR Mobile triggering feature, users can instruct the ObserVR1000 to perform an automatic action such as record or power off. Triggering can replace a repetitive action, thereby saving time, and/or ensuring specific parameters are met. The user can define one or multiple custom behaviors for greater ease and accuracy during vibration testing.

The controller can recognize various system events such as analog/digital channel input, power state, and time of day. The action may include starting a recording, turning a digital output on/off, or powering off the device. Users can set a trigger for more precise testing or simply for convenience.

Data Analysis

Following data recording, there is a multitude of options for data analysis. To learn more about the ObserVIEW analysis software from Vibration Research, visit the VRU Course Getting Started with ObserVIEW.