What is a Signal?

October 19, 2021

Fundamentals

Waveform Display

Domains for Analysis

Random Vibration

Back to: Introduction to Vibration Signals

The signal is a basic concept in vibration testing, but its fundamentals are necessary for engineers to understand. Simply put, signals are messengers. They define the vibration that excites the device under test (DUT) and send data from the DUT back to the vibration controller. Afterward, the engineer can analyze the vibration signal.

A testing facility can use signal analysis to:

- Confirm the longevity of a device based on average wear

- Determine a device’s response to a transient event

- Qualify a device according to safety standards

- Perform preventative maintenance and regular monitoring of equipment

- And more

Vibration Signal Analysis Setup

An event must occur for a signal to be set in motion. In electronic applications, a signal is generated by:

- varying the voltage or amperage in an electric current or

- changing the amplitude or frequency of an electromagnetic wave.

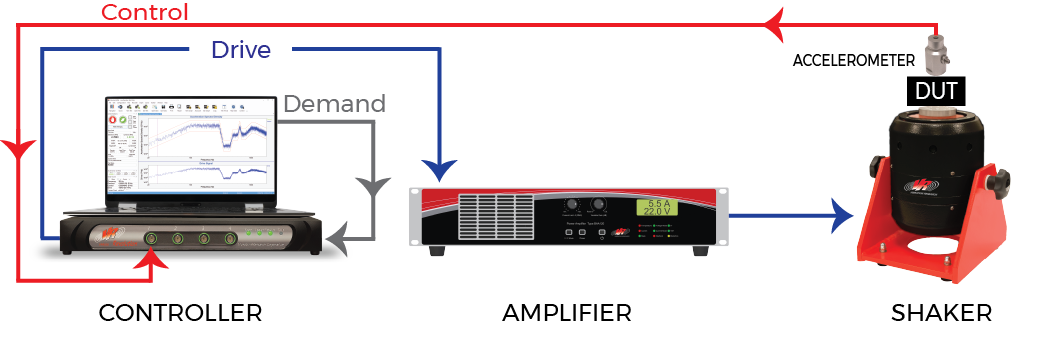

Vibration testing systems have several main components that transmit electrical signals. The primary ones are the vibration controller, power amplifier, electro-dynamic shaker, and control sensor.

Figure 1.1. A vibration testing system including a vibration controller, power amplifier, shaker, DUT, and transducer (control sensor).

Closed-loop Control

A vibration testing system runs in a closed-loop operation. The vibration controller sends a signal to the shaker via the power amplifier. Then, a drive signal generates shaker excitation in a controlled manner. In short, controllers are responsible for the vibration observed on the shaker head.

Next, a control sensor measures the DUT’s response to the vibration and converts the data into an electrical signal. The controller receives this signal and relays the information to vibration control software such as VibrationVIEW. Remote inputs and outputs, such as current and voltage monitors and low voltage relays, also send data to the controller.