Measure the Controller Noise Floor

February 13, 2020

Back to: System Noise and Ground Loops

Measuring the controller noise floor is the first step in determining the source of noise in a vibration testing system.

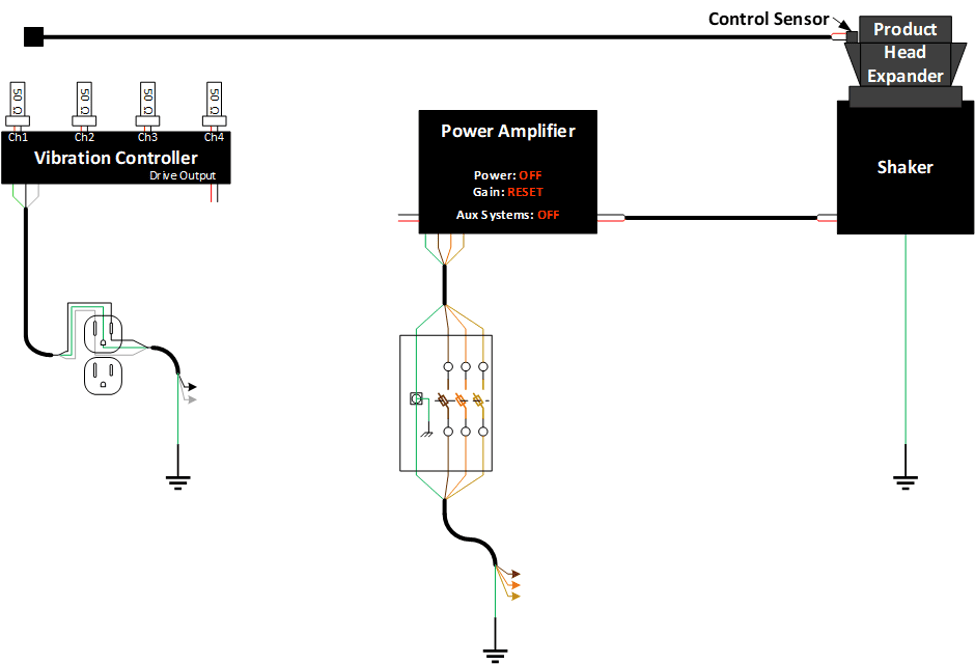

- Power down the amplifier, blower, hydraulic pumps, and any other auxiliary systems.

- Disconnect the sensors from the controller.

- Remove any products or fixtures from the slip table or head expander.

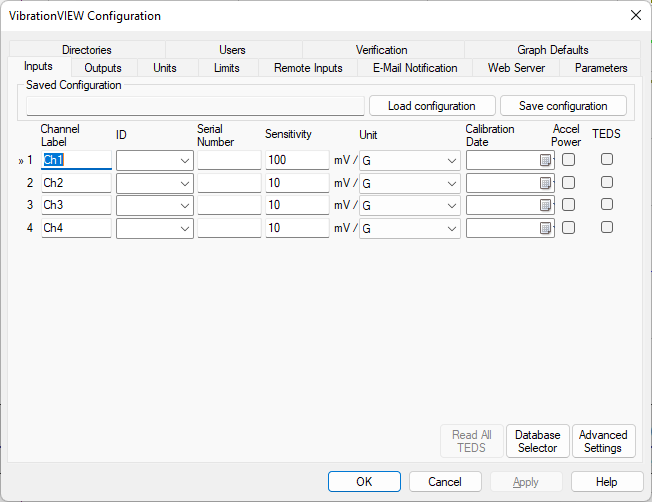

- Configure the inputs in VibrationVIEW.

- Select Configuration > Inputs.

- Set the Ch1 sensitivity to the sensitivity of the control sensor; the appropriate sensitivity will ensure that all recorded values are comparable and at the same relative level.

- De-select the Accel Power checkbox for the Ch1 input.

Inputs tab in VibrationVIEW.

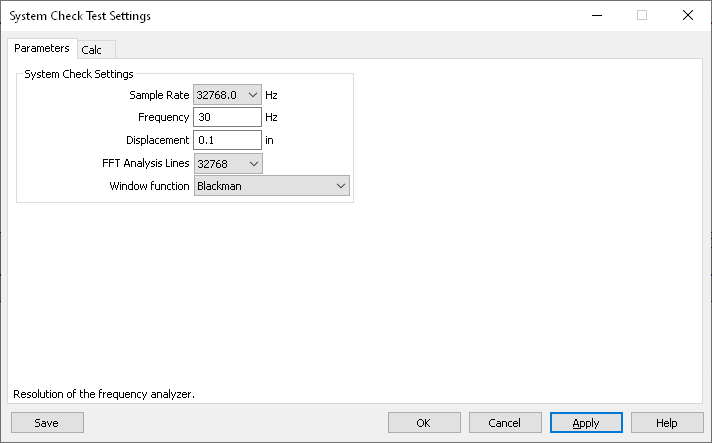

- Configure System Check.

- Select Test > Test Type > System Check.

- Select the Edit Test button and set the sample rate to 32,768Hz and FFT analysis lines to 32,768. These settings will give a 0.5Hz resolution out to 16kHz.

- The default graphs in System Check should be an acceleration waveform and acceleration spectrum. If the display does not include one or both graphs, add the graph(s).

- Measure the controller’s base noise floor.

- Terminate the controller inputs by shorting the input pin to the input shell with a 50-75ohm BNC terminator or jumper.

- Verify that the amplifier’s power is off and the gain status is RESET.

- Disconnect the drive cable between the controller and the amplifier.

- After 10 seconds, select the Save Data button and name the file “1 – Controller Noise Floor.”

This data file will serve as a reference for troubleshooting. It is the lowest amount of noise that will always be visible in the system.

Figure 2.1. Configuration to measure the noise floor.