An In-Depth Look into Classical Shock Pulses

April 13, 2020

Back to: Shock Testing

“Classical” shock pulses are a classification of shock pulses in the vibration testing industry. The various types of classical shock pulses serve different purposes. Generally, they are a unipolar pulse that excites a wide range of frequencies in a short period of time, just in different ways. Unipolar pulses consist of a single, brief impulse in the positive or negative direction without crossing the zero line.

Classical pulses are primarily defined in acceleration. The shape of the acceleration waveform determines the pulse’s frequency range and the frequencies’ excitation. However, the change in velocity (ΔV) determines the shock severity.

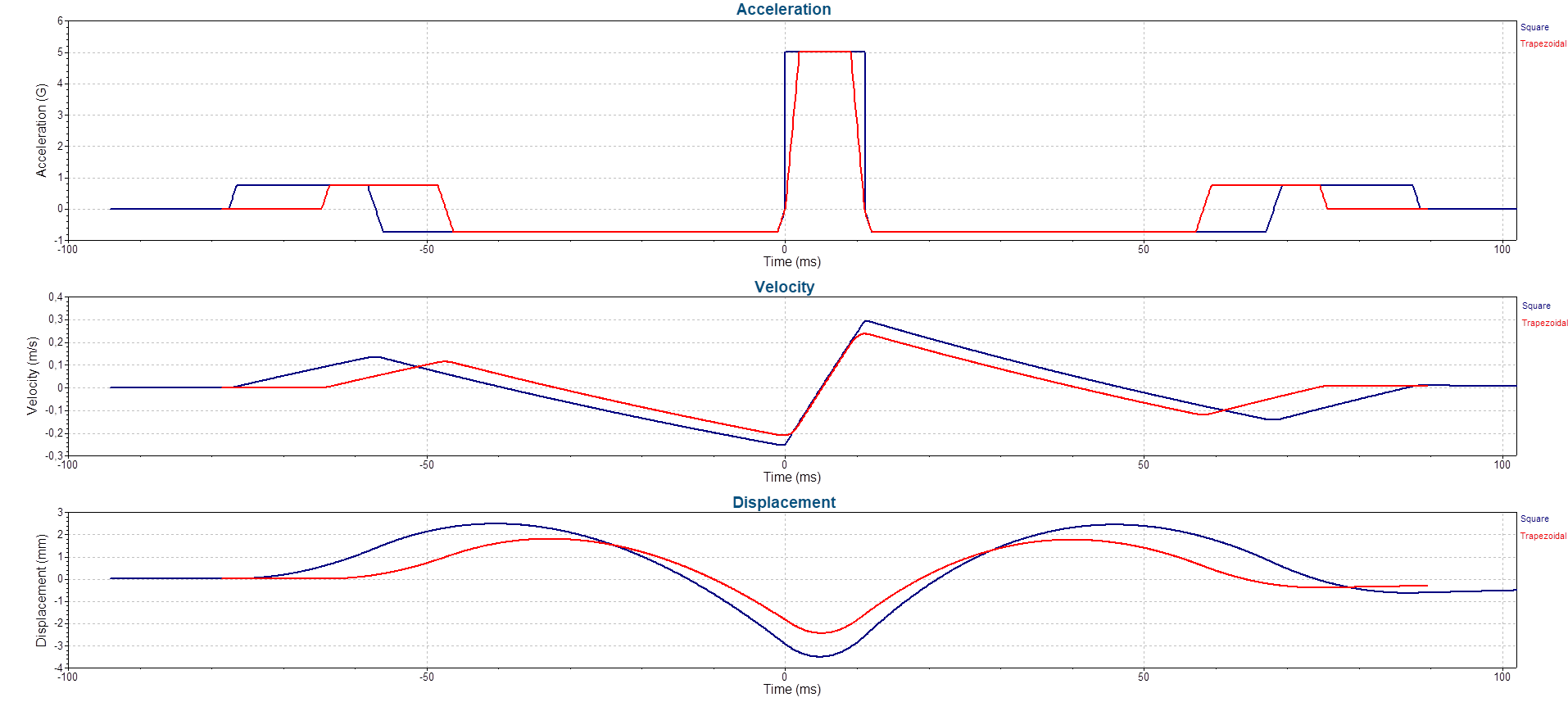

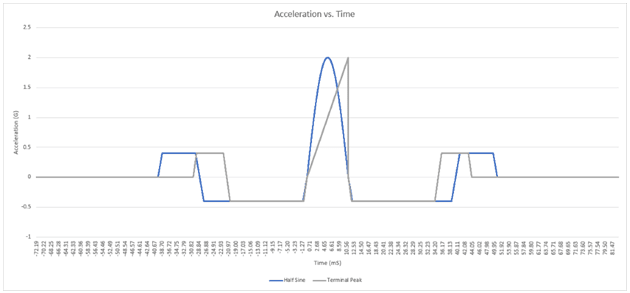

Looking at classical shock pulses on a graph, we can note the differences between the pulse shapes (Figure 1.1). The pulse was defined in acceleration, and the test data was converted to velocity and displacement for comparison.

Figure 1.1. Shapes of various classical shock pulses.

Half-Sine and Terminal-Peak Pulses

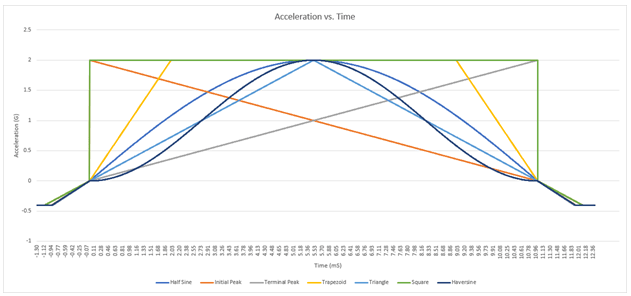

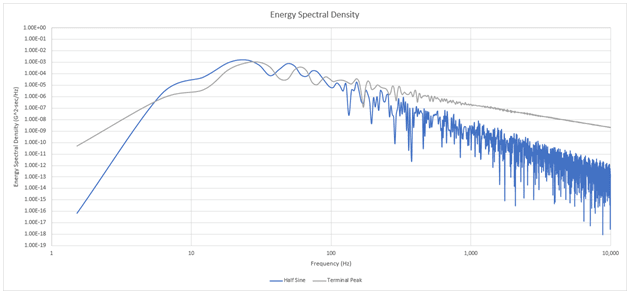

Half-sine and terminal-peak are two of the more common classical shock pulses in the vibration testing industry. They are included in many test specifications for different applications. In Figure 1.2, the two acceleration waveforms show the difference between the half-sine and terminal-peak shapes.

Figure 1.2. Half-sine (blue) and terminal-peak (grey) pulses.

The waveform dips below the zero amplitude before and after the unipolar pulse. However, the unipolar pulse, which carries significant energy and represents the intended excitation, is one-directional. Another lesson in this course discusses pre/post-pulse compensation.

Half-sine Pulse

The half-sine pulse transitions smoothly, and all change is uniform. Most of its wavelength energy occurs at low frequencies, and it generates lower amplitudes at higher frequencies. Half-sine pulses are primarily used to test for responses and resonances in mechanical systems.

Terminal-peak Pulse

The terminal-peak pulse has a smooth ramp up/down and a sharp transition back to zero. The sharp transition generates notably higher amounts of high-frequency energy. This energy generates minimal displacement and affects mechanical resonances less than the half-sine pulse.

Terminal-peak pulses are effective for testing electronic components, solder joints, and electronic circuitry. Its high-frequency energy excites potential failures in these components, and engineers often select it when testing components with embedded electronics.

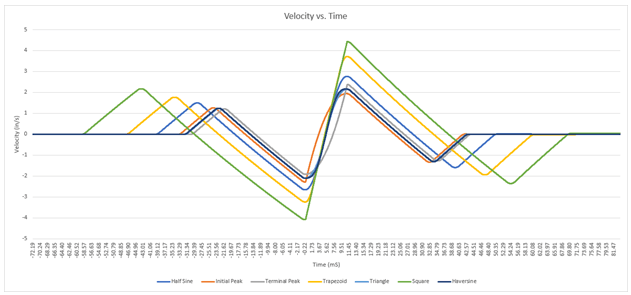

Figure 1.3. Half-sine (blue) and terminal peak (grey) pulses (energy spectral density).

Visually, the differences between the half-sine and terminal-peak pulse shapes are easy to see (Figure 1.3). When running the pulses on a shaker, the overall velocity and displacement of the terminal peak are lower, but the amount of high-frequency energy generated by the terminal peak is much greater. These characteristics must be evaluated when selecting a classical shock pulse.

Square and Trapezoid Pulses

Square and trapezoid pulses appear as extreme outliers in the displacement and velocity waveform plots (Figure 1.4). Neither pulse shape is common in the vibration testing industry.

The square pulse will never be perfectly square on any mechanical system. A mechanical system cannot change positions so sharply and the square wave will always have some trapezoidal shape.

The trapezoidal pulse is also difficult to create with a mechanical system due to its constant acceleration at the peak. There are shock machines designed to create trapezoidal pulses that typically use pneumatics to propel the table up and down. These pulses are exceptionally difficult to produce on electrodynamic, hydraulic, and other shaker systems that are limited in velocity and displacement.

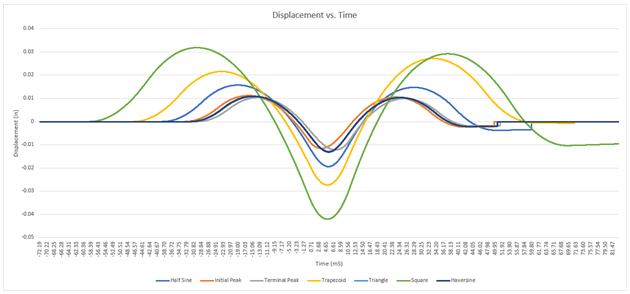

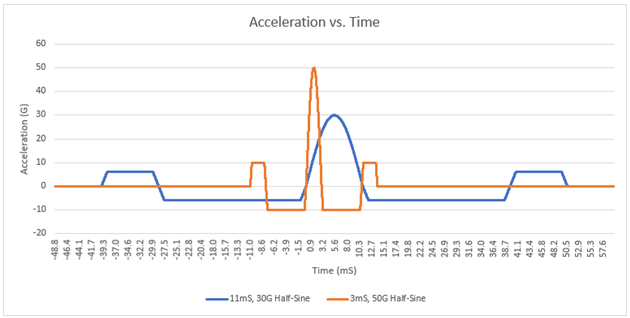

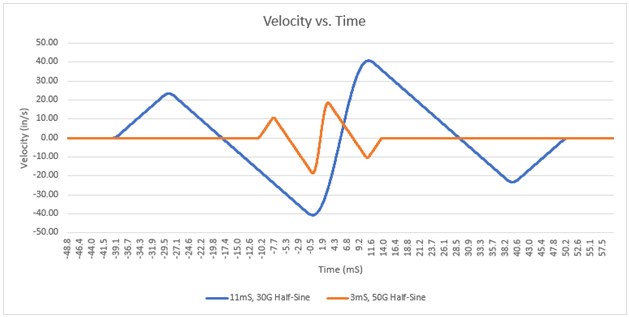

Test Standards and Multiple Shock Pulses

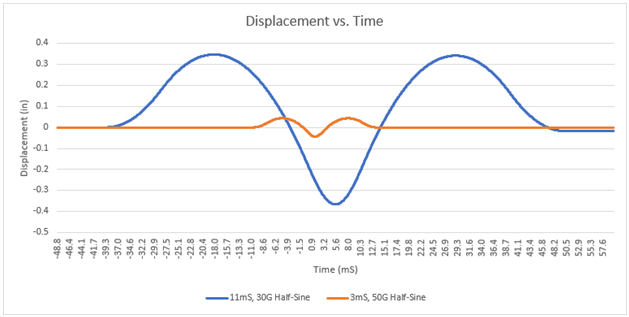

Test standards often require an engineer to run multiple shock pulses with different amplitudes and durations. For example, EN-60068-2-27 specifies two pulses: a 30G, 11mS half-sine pulse and a 50G, 3mS half-sine pulse (Figure 1.5).

Although lower in peak amplitude, the 30G pulse will generate a larger amount of displacement and velocity and a lower amount of overall high-frequency excitation. The 50G pulse will have less displacement and velocity but a much higher energy spectral density at higher frequencies.

The combination of shock pulses is very common in test specifications. The first, longer-duration pulse is designed to excite lower frequency mechanical resonances. The second pulse drives the higher frequencies and can cause more damage if the product’s resonances are in bands of higher frequency.

Figure 1.5. EN-60068-2-27 specifications for multiple half-sine pulses.

Moving Toward Complex Shock Pulses

More often, vibration test specifications are recommending real-world data to generate test profiles. Requirements are moving away from classical shock pulses and are instead using a complex time-history waveform, the shock response spectrum (SRS), or a combination of both. Complex shock pulses are the more appropriate and realistic method of evaluating a product’s response to real-world environments.

Conclusion

Classical shock pulses excite a range of frequencies in a short period of time, and each pulse shape serves a different purpose. In the end, no classical shock pulse occurs in the real world; rather, they are historical references that have been used for many years and are still valid for evaluating products.