Characterizing Potential Excitations in the Field

June 8, 2023

Back to: Resonance in Product Development

Data recording is the most effective method of characterizing excitation that a product may experience in the field. Engineers want their test profiles to reflect the operational environment to avoid unwarranted fatigue damage post-production. The article “Why Use Field-recorded Data to Develop a Test Profile?” states:

“Data from the field offers a realistic look into a product’s operational environment. A test profile that is as close to the end-use environment as possible leads to an efficient testing process and a quality product.”

After recording, engineers can review the data to identify transient excitation, vibration at the system’s resonant frequencies, and steady-state motion that leads to fatigue damage.

Additional Uses

Recorded data offers a plethora of additional insights for laboratory testing.

Post-process analysis can confirm digital twin assumptions and help define appropriate analysis and test acceleration methodologies and requirements for test equipment. These measurements can also confirm that the shaker, DUT fixturing, and control are delivering good results and verify that field failures match test failures.

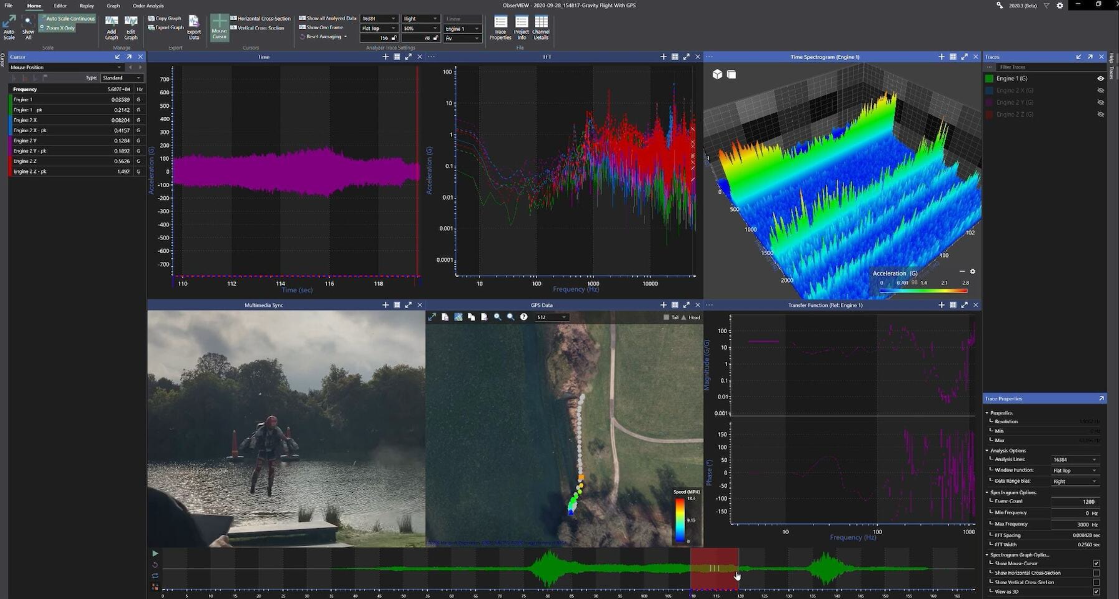

Recorded field data in ObserVIEW.

Recording Field Data

Today, it is easier than ever to capture field data using a digital data acquisition system. Data acquisition systems like the ObserVR1000 are portable devices that allow engineers to record and analyze data quickly, both in the field and post-process.

With the ObserVR1000 and the ObserVIEW analysis software, engineers can perform a live data analysis to see in real-time what is happening in the time and frequency domains and how damage accumulates over them.

After recording, they can review the operational environment and generate a test profile. Analysis software like Fatigue Damage Spectrum or Shock Response Spectrum can output accelerated test profiles from recorded data. The result is a test profile that is equivalent to the product’s end use.

ObserVR1000

Designing a Realistic Test Plan

“Why Use Field-recorded Data” also includes steps for designing a test plan that simulates the product’s operational field:

- Evaluate the stress level and the usage profile for the field environment

- Select the appropriate acceleration model(s) for the test based on the expected failure mechanism

- Define the appropriate stress level and test duration based on the test equipment’s capabilities and the maximum allowable stress level to avoid “foolish” failures

- Calculate the acceleration factor and duration of the test based on the field stress level and the environmental exposure time for lifetime operation

- Use a sampling plan derived from stress/strength interference principles