Velocity and Displacement Sensors

June 10, 2022

Back to: Sensors for Vibration Testing

Following accelerometers, the most common transducers in the vibration testing industry are displacement and velocity sensors.

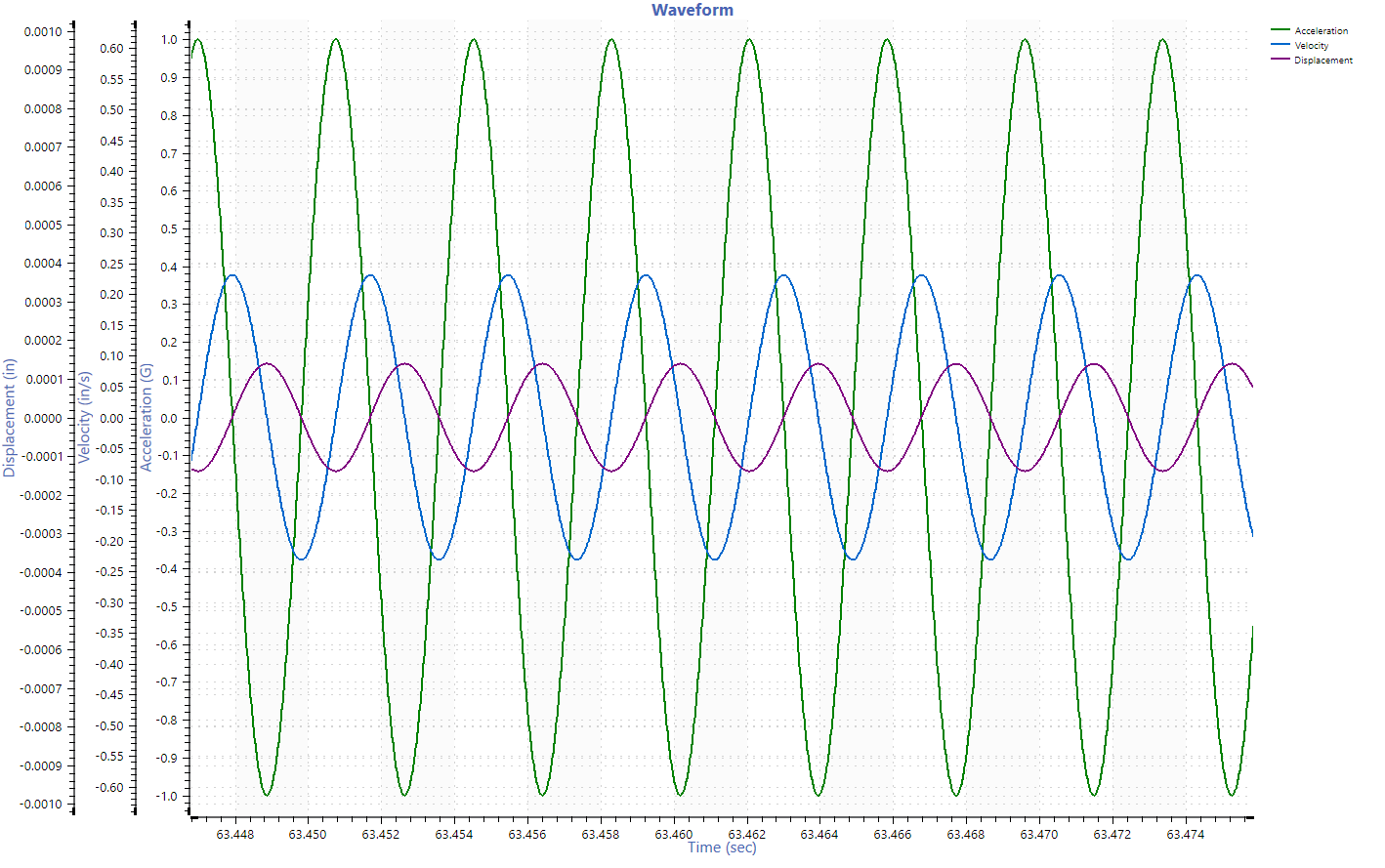

Acceleration, velocity, and displacement measure changes in a waveform as a function of time. These sinusoidal measurements are directly related, so engineers can collect one and convert it to another.

Vibration engineers do not often measure acceleration, velocity, and displacement simultaneously because they require different measurement tools that can be complex and expensive. As accelerometers are affordable and conventional, conversion is a convenient option for those that have accelerometers but require velocity or displacement data.

Displacement Sensors

Displacement is a measurement of the change in position of an object. The change is then converted to a unit of distance, such as meters.

Displacement sensors measure the relative displacement of an object, meaning the change in position of an object relative to another. The reference point may be the object’s original location or another object, and the measurement can be linear or rotational movement or displacement following contact.

How a displacement sensor measures a change in position depends on its type. Eddy current displacement sensors use a magnetic field, capacitive displacement sensors use an electrical charge, optical displacement sensors use a light source, etc. Many of these sensors are non-contact.

Applications

Displacement sensors are effective and accurate at low frequencies (around 0-10Hz). They are common in seismology and earthquake testing because detection of low-frequency vibration at a high resolution is critical to safety.

An engineer may also select a displacement sensor when they suspect a failure mode is a result of displacement, such as in the case of unbalance in rotating machinery. For example, condition monitoring applications often use eddy current sensors (proximity probes).

Engineers must account for noise when using displacement sensors. Acceleration values are low at frequencies less than 10Hz, and the noise floor may hide the signal if the sensor does not produce a strong enough output signal without amplifier gain. However, signal gain also amplifies noise levels.

Conversion from Acceleration to Displacement

At high frequencies, displacement measurements are small, and displacement sensors are ineffective at detecting changes in position. Instead, engineers can record high-frequency signals with an accelerometer and use the process of double integration to convert them to displacement.

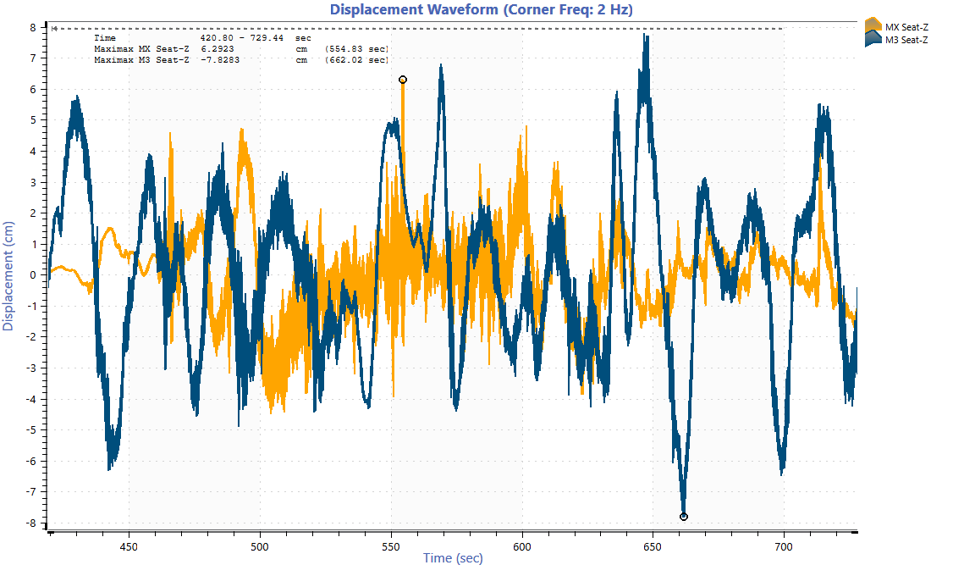

Double integration alone introduces noise into the signal. The original signal must be filtered or processed to remove this potential for error. A high-pass filter with a proper corner frequency is an effective option for pre-processing data.

The cutoff frequency, or corner frequency, is the minimum value the unit conversion allows through the integration high-pass filter. The cutoff frequency value should be the lowest valid signal frequency for the sensor and device under test. A value lower than the measurement’s frequency range will produce an output that does not start or end near zero. A cutoff frequency that is too high will limit the low-frequency data, thereby removing valid data.

Velocity Sensors

Velocity measures the change in displacement in one direction over time (m/s). Velocity can be a positive or negative value, but its magnitude is speed, which is always positive. The average velocity is the total displacement over a defined period divided by time, and instantaneous velocity describes one moment in time.

Velocity sensors measure the relative linear or angular speed of an object. Traditional velocity sensors are electromagnetic, but there are also piezoelectric ones, which are accelerometers with an internal integrator. Triaxial sensors measure velocity in the axial, horizontal, and vertical directions.

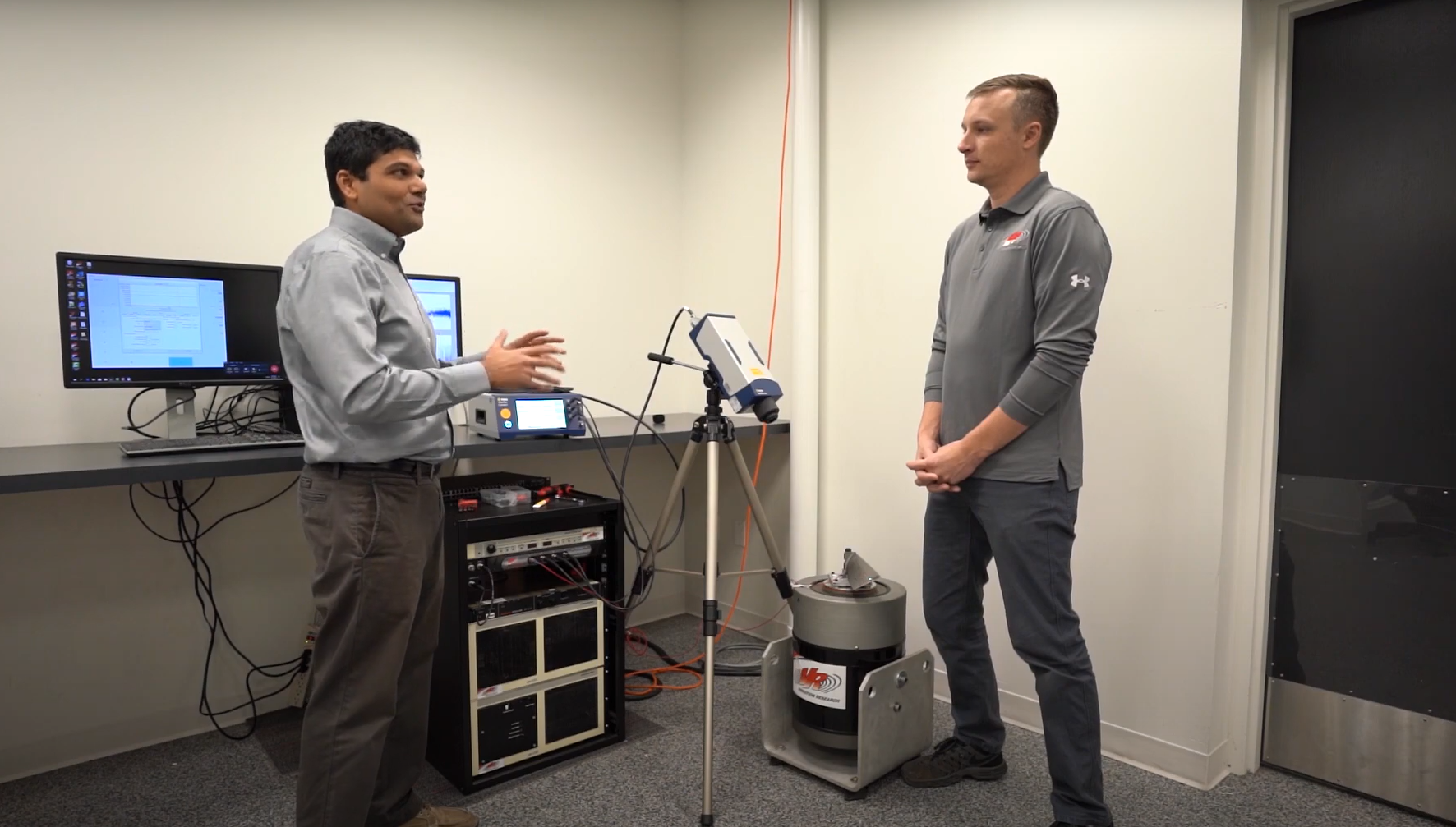

Laser vibrometers measure velocity using the doppler effect. They detect a light waveform’s shift in frequency after it backscatters from the measurement surface.

Like accelerometers, velocity sensors are not effective at low frequencies (<10Hz). They do not provide quality data at frequencies above 2kHz either. As such, these sensors are preferable only at mid-range frequencies where a displacement/acceleration sensor functions poorly.

In particular, velocity measurements at mid-range frequencies can help determine the severity of rotating machines. Engineers use this information to diagnose defective components like bearings or gears.