Single-axis Vibration Testing

March 29, 2022

Multi-Axis Testing

Back to: Multi-shaker Control

Single-axis, single-shaker control is the traditional method of vibration testing. A test engineer exposes a device under test (DUT) to a single-axis excitation. Optionally, they can rotate and remount the DUT to test it in the subsequent orthogonal axes.

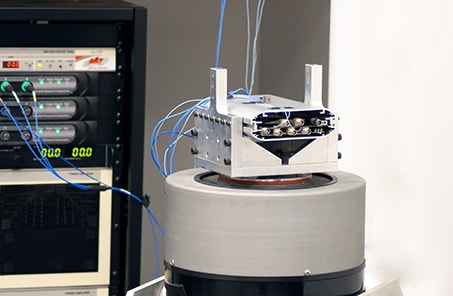

Figure 4. Single-axis vibration test on a shaker.

A single-axis test assumes that the vibration of each axis is independent. Due to its historical prevalence, single-axis testing is a common method and is the model for many test standards.

When to Use Single-axis Testing

Many test standards call for a single-axis sine or random test. Engineers can accomplish many test goals with a single-axis test. It is an accessible test method that, at a minimum, requires one shaker and basic software. Engineers can use advanced applications if desired.

With a single-axis shaker, a test engineer can determine the resonant frequency of a DUT from a sine sweep test. They can then run a sine dwell or random test to bring the product to failure. A single-axis system can perform classical and complex shock tests, mixed-mode vibration, accelerated test profiles, fatigue tests, and more. In fact, many engineers will find single-axis systems to be more than sufficient for their testing needs.

Constraints

A single-axis test cannot always capture the multi-directional vibrations of complex structures. Single-axis testing is more time-consuming than its multi-axis counterpart and does not account for the interaction of excitation paths and combined loading. What test items might pass in a single-axis test may fail in service.

However, multi-axis testing still requires more technological advancement. Multi-axis equipment is more expensive and not prevalent in every industry. Many testing standards still require single-axis tests, although some test labs are choosing to perform multi-axis testing to improve product quality.

It is important to note that these are simply constraints of single-axis testing. It is an acceptable and widely used vibration testing method.

Frequency Rating

As Clyde Harman and Michael B. Pickel note in the research paper “Multi-Axis Vibration Reduces Test Time,” most servo-hydraulic shaker systems are limited to several hundred hertz. There are multi-axis shakers on the market capable of handling high-frequency tests. However, many industries are still limited to a single axis for tests that exceed standard shaker limits.

As the goal of lab testing is to avoid the cost and time of field testing, single-axis testing will prevail until technology advances and multi-axis testing becomes more prevalent.