Introduction to Multi-Axis Testing

March 29, 2018

Multi-Axis Testing

Back to: Multi-shaker Control

Multi-axis vibration testing is gaining popularity in the automotive industry and other sectors. A vehicle experiences vibrations along several axes when it travels. Therefore, it makes sense for engineers to test products along multiple axes.

Traditionally, engineers have run tests one axis at a time. They mount the device under test (DUT) to a single-axis shaker and run the test profile on one axis. Next, they dismount the DUT, reorient and remount it, and perform the test on a second axis. Then they repeat the process on a third axis.

With advanced machinery, engineers can now test products along multiple axes at once. In addition to being time-efficient, multi-axis vibration testing can fatigue the DUT to faster. A product may pass a sequential, single-axis test but fail a more realistic multi-axis test of the same duration. For this reason and others, multi-axis vibration testing is becoming increasingly popular.

Types of Multi-axis Vibration Tests

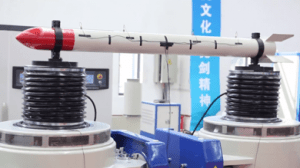

Figure 1. A MESA shaker configuration.

There are many ways to configure a multi-axis vibration test. The two key characteristics of any configuration are the number of shakers and the number of axes or degrees of freedom. Let’s consider some examples.

Multi-exciter/Single-axis

A MESA (multi-exciter/single-axis) configuration consists of two or more shakers that move in the same direction along one axis. Engineers use this configuration to test oversized devices that require a shaker on each end. The shakers are often synchronized, and the controller(s) output the same test profile (see Figure 1).

Figure 2. A four-post shaker system testing a full vehicle.

A four-post configuration moves four shakers along the same axis. Automotive engineers often use this method for full vehicle testing. They set the vehicle on four shakers—one under each wheel—and play back recorded field data files from each wheel (see Figure 2). Then they play back the recorded vibrations simultaneously as if the vehicle were in motion.

Four-post testing is one of many multi-shaker methods the automotive industry may employ. Another common application is squeak and rattle testing. No automobile driver likes a squeaky seat, but a seat must experience a particular set of vibrations along more than one axis before it emits a noise. Only multi-axis testing can simulate this real-world scenario.

Watch Vibration Research controlling a four-post shaker at TUV America (YouTube).

Multi-exciter/Multi-axis

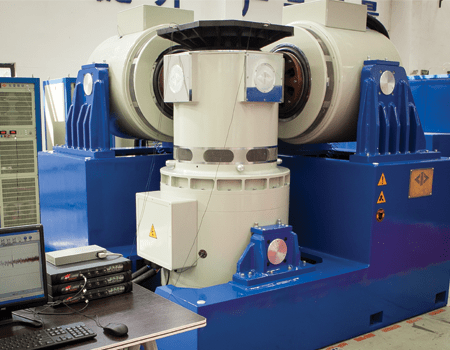

In recent years, the automotive industry has had an increased interest in other multi-axis shaker configurations. The three-axis configuration belongs to the MEMA (multi-exciter/multi-axis) class. This method consists of at least three shakers and simultaneous motion along the x-, y-, and z-axes (see Figure 3).

Figure 3. A three-axis shaker system with a table.

Component or sub-system testing is the primary use of the three-axis configuration. It is accomplished by performing a random vibration test along each axis using identical or individual test profiles.

The three-axis configuration can create a more realistic test compared to traditional single-axis testing. A vehicle experiences vibration from several directions simultaneously, and the three-axis configuration accommodates the three linear directions of motion.

However, three-axis testing does not accommodate the three rotational directions of motion: roll, pitch, and yaw. A six degrees-of-freedom (6-DOF) system handles all six: x, y, z, roll, pitch, and yaw. There are numerous ways to configure a 6-DOF system.

HALT/HASS chambers are sometimes labeled as 6-DOF systems because they can apply vibration simultaneously in the three linear and rotational axes. However, these systems differ from the multi-shaker testing discussed in this course.

Conclusion

The potential advantages of multi-axis testing are clear. Multi-axis vibration testing can bring products to fatigue failure faster and, in some instances, is more realistic than sequential, single-axis testing. The remainder of this course will discuss these key differences and move into the considerations and system configurations of multi-axis testing.