Power On Auxiliary Systems

February 13, 2020

Back to: System Noise and Ground Loops

After measuring noise with the control sensor connected, check for noise related to the auxiliary systems.

- Power on the blower, oil pump, hydraulics, and any other auxiliary systems.

- After 10 seconds, select the Save Data button and name the file “3 – Auxiliary Systems.”

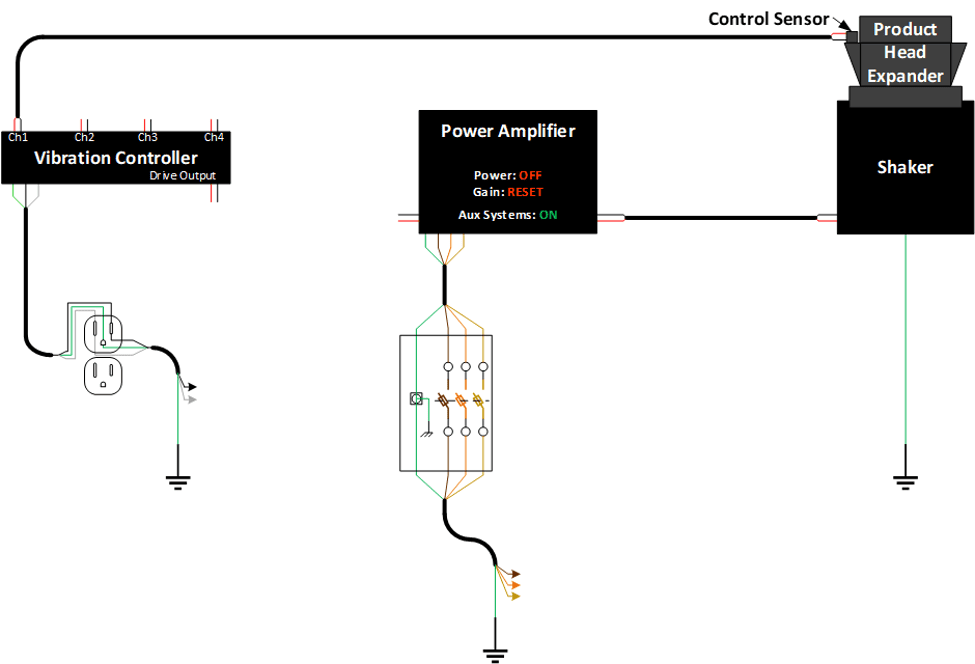

Figure 2.3. Vibration system configuration with auxiliary systems powered on.

Sources of Noise

Compare the signal levels to the “sensor connected” data. Any new noise sources can be attributed to:

- EMI from an auxiliary component picked up by the accelerometer cable. Properly ground the components and, if needed, shield the sensor cable from the EMI.

- Vibrating armature due to mechanical issues such as loose screws or insecure mounting. Tighten components as needed.

Determining the Noise Source

If you need help determining the noise source, take the following steps:

- Feel the shaker head to see if it is vibrating.

- Disconnect the accelerometer from the shaker head but keep the cable in the same location.

- Short the accelerometer shell to the ground screw on the back of the I/O unit. This step will reduce interference from other equipment (if any is present). If there is interference, jumpers can be installed on the VR9500 to bypass the protective fuse and short the shell to ground. Contact Vibration Research for details.