Multi-loop with Phase Control

March 29, 2022

Multi-Axis Testing

Back to: Multi-shaker Control

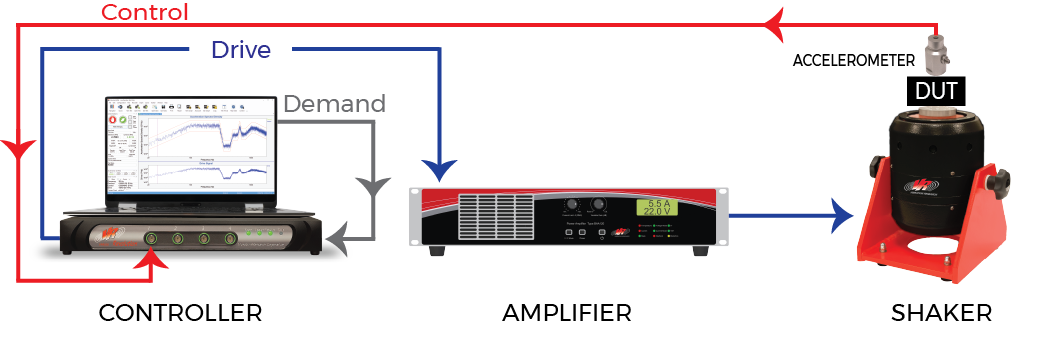

A vibration controller creates a “loop” with the shaker and device under test (DUT) by sending an analog signal to the power amplifier driving the shaker. It produces the drive signal by comparing the control acceleration measured on the shaker table or DUT with the demand reference. The control algorithm minimizes the difference between the control and demand signals by adjusting the shape and amplitude of the drive signal.

This referencing of control and demand forms what is called a control loop. When the controller(s) send independent drive signals to multiple shakers, such as in multi-shaker testing, the system performs multi-loop control.

Multi-loop Phase Control

Multi-loop phase control synchronizes two or more shakers moving along the same axis while maintaining phase through level changes.

Multi-loop phase control is ideal for oversized or heavy test items, as multiple shakers distribute the load throughout the structure. Shakers can be configured in several ways for a multi-loop phase test.

Multi-loop phase control is ideal for oversized or heavy test items, as multiple shakers distribute the load throughout the structure. Shakers can be configured in several ways for a multi-loop phase test.

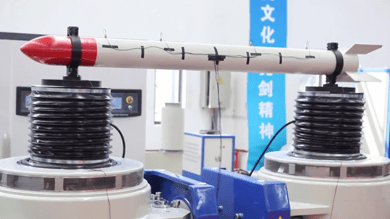

For example, dual (or dualing) shakers is a type of multi-loop phase control. Two shakers are in a push-push configuration if they face the same direction. When facing one another, they are in a push-pull configuration.

Fixture Design

Multi-loop phase control is also an appropriate choice when mounting the DUT on a single shaker would be unrealistic. Some test items have multiple mounting points in the field, and a multi-exciter/single-axis (MESA) test would be more reflective of that environment.

In the article “Multi-Axis Vibration Testing of an Aerodynamically Excited Structure,” Chris Roberts and D. Ewins note that the test environment for items like rockets can vary significantly from the service environment, especially at the item’s extremities.

“The main causes for this mismatch can largely be attributed to the test setup itself, as fixture designs rarely replicate the in-service boundary conditions realistically and the excitation path in the test can also be very different from that in service.”

In other cases, a system may require a large shaker to meet the force requirements, lowering the usable frequency range. Using two shakers increases the force rating while maintaining the frequency range.

Forced Synchronization

Rigid coupling generally does not work well for multi-loop phase control. If one of the shakers moves out of phase, then the potential for damage increases. Instead, a dynamic coupling of the shakers is ideal, where both shakers monitor the control and adjust the drive when necessary.

In the article “Multi-Shaker Control: A Review of the Evolving State-of-the-Art,” Dr. Marcos A. Underwood, Tony Keller, and Russ Ayres state that the proper control method, “…has been found and field proven … in maintaining limit control of one or more limit channels while maintaining proper amplitude, phase, and coherence control and without violating any important structural constraints.”