How Do I Trust Third-party Lab Results?

July 22, 2024

Initial Design

Data Analysis

Reporting

Back to: Making Sense of Test Data

Confidence in test data comes from running a “good” test. Throughout this course, we’ve reviewed several elements of a good vibration test. In the first lesson, we discussed gathering preliminary information to build a test profile, including reviewing product specifications, analyzing the device under test (DUT), and assessing the end-use environment.

A good test also depends on the quality of recorded data (if applicable), such as in the case of a fatigue damage spectrum test, and the processing of that data. Although only mentioned briefly in this course, the proper fixturing and control of the test are also imperative to quality test execution.

If your lab is unable to achieve one or multiple of these elements, it may turn to a third-party lab. Then the question becomes, how do I trust third-party lab results? There are many trustworthy test labs, but it is reasonable to need assurance that the provided test data are valid.

Third-party Labs

Checking a lab’s accreditations can go a long way in determining its credibility. Third-party accreditations require labs to maintain certain processes and perform regular audits. If you decide which accreditations meet your standards ahead of time, it will be easier to find a trustworthy lab.

There are also questions you can ask the test lab, such as:

- What quality control measures do you have in place?

- What is your shaker maintenance procedure?

- What is your controller calibration frequency/method?

- Do you run tests 24/7 or interrupt them daily, weekly, or on holidays?

- What test monitoring do you have in place?

- Will the test setup automatically shut down? If so, based on what parameters?

- How often do you check the test, and what do you check for?

Auditing the Data

If needed, you can request certain documentation or preliminary measurements to confirm that a third-party lab’s shaker system is in working order. If performing tests internally, a lab can collect this data for greater confidence in their results. Requests may include:

Verification of control accelerometer calibration

A valid calibration certificate confirms that the control sensor’s readings are trustworthy at the time of calibration.

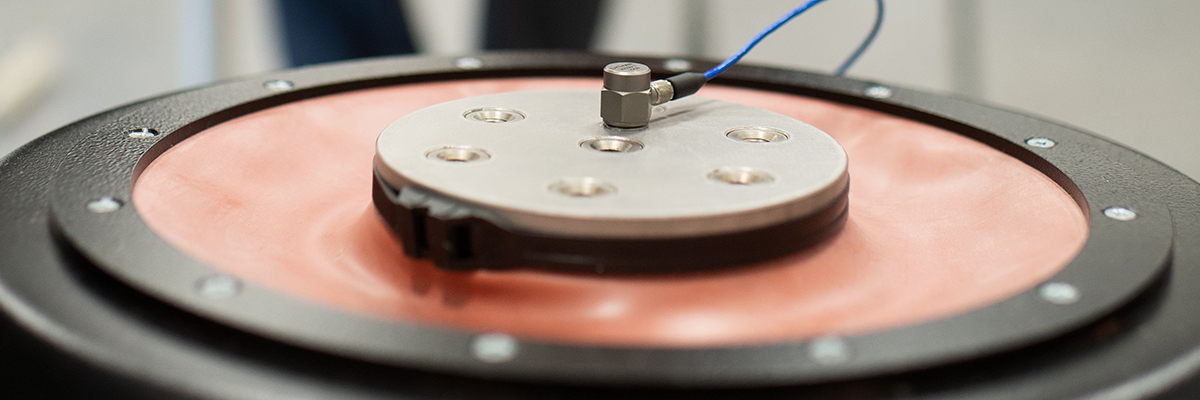

Sine sweep resonance search of the fixture with the DUT

A comparison of the DUT’s natural frequencies to a resonance search of the fixture with the DUT may indicate a need for addressing external influences (such as inadequate fixture stiffness, poor implementation of fasteners, or excessive cross-axis sensitivity) or shaker maintenance.

Measurement of off-axis noise

Significant off-axis noise from the shaker can affect the DUT’s behavior and indicate the shaker needs service.

Control scheme sensitivity analysis

The correct control scheme optimizes test outcome and helps to ensure that relevant data are measured.

FDS or SRS plot of test response

Comparing an FDS/SRS plot of the test response to a standard will indicate if the shaker test is damaging enough/too damaging.

Kurtosis setting

The correct kurtosis setting ensures the test includes any high-amplitude peaks likely to occur in the field environment.

Evidence of peak clipping

Similar to the kurtosis setting, evidence of peak clipping may indicate that the test removed high-amplitude peaks likely to occur in the field environment.

Documentation supporting the use of correct fastener torques

Test inspection log

For some of these examples, you may need to compare the data to a standard/baseline to confirm the acceptability of the system. You can also request this information in the report.

Using Field Data to Verify Results

When comparing third-party results, engineers can use recorded field data to evaluate three key areas of test quality:

Confirm the function of lab equipment

Comparing laboratory vibration data to field recordings helps identify anomalies caused by instrumentation or control issues, such as sensor misalignment, channel cross-talk, incorrect drive levels, or shaker system malfunctions. A significant mismatch between field and lab response spectra can indicate that the test system is not reproducing the intended input.

Verify the test’s state of control

Even when using calibrated equipment, improper control strategies can distort test accuracy. Field data allow engineers to check that the control accelerometers, feedback loops, and drive signals are maintaining stable and representative conditions throughout the test duration. A well-controlled test should reproduce the same dominant frequencies, overall vibration levels, and statistical properties observed in the field.

Compare results to industry standards and prior tests

Field data can also help engineers confirm that the test aligns with relevant industry specifications (such as MIL-STD-810, ISTA, or ISO standards) and previous testing on similar products. When differences arise, engineers can determine whether the discrepancy reflects a meaningful environmental variation or a laboratory setup issue.