Tools for Testing

March 29, 2018

Back to: Getting Started with VibrationVIEW

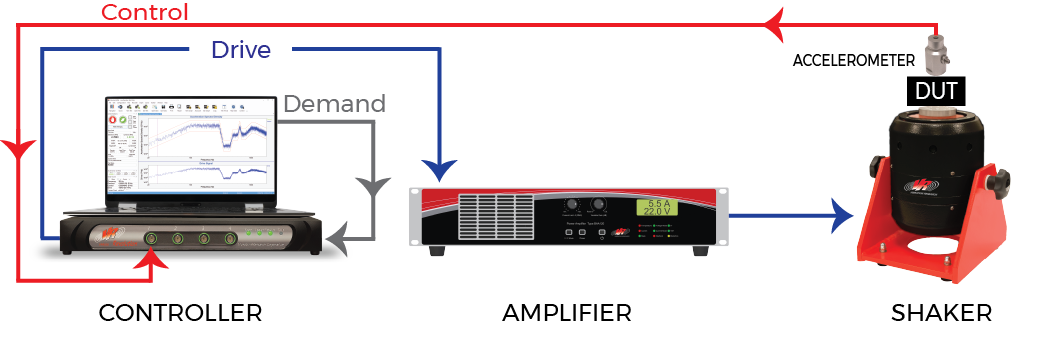

The basic components required for closed-loop vibration testing are:

- Test control and analysis software, such as VibrationVIEW

- Vibration controller, such as the VR9500, VR10500, or ObserVR1000

- Power amplifier

- Electro-dynamic or servo-hydraulic shaker

- Transducer (typically an accelerometer)

VibrationVIEW includes System Check to test and calibrate a system. Optional VibrationVIEW software modules include Sine, Random, Shock, Field Data Replication (FDR), and many more.

Each module has various sub-options focused on specific test requirements. For tutorials on how to run tests and create reports in VibrationVIEW, take the VibrationVIEW Syllabus course.

VibrationVIEW is capable of operating without a shaker in Demonstration Mode. This mode generates simulated data as if the test profiles were being run on a shaker.

Note: The sample test profiles provided in VibrationVIEW are designed for Demonstration Mode only. Before running a test on a shaker, make sure the System Limits are properly set or the shaker could be damaged.

Vibration Controllers

Controllers send signals to the shaker via the power amplifier to generate shaker excitation in a controlled manner as defined by a specific output signal. They are responsible for the vibration observed on the shaker head. Controllers also receive data from transducers and information via remote inputs/outputs (e.g., current and voltage monitors, low voltage relays, etc.).

The VR9500, VR10500, and ObserVR1000 can all be used as a vibration controller. The ObserVR1000 also functions as a dynamic signal analyzer.