Post-test Review of Recorded Shaker Test Data

January 6, 2026

Measuring Field Environments

Test Monitoring in the Lab

Back to: Recording & Implementing Vibration Test Data

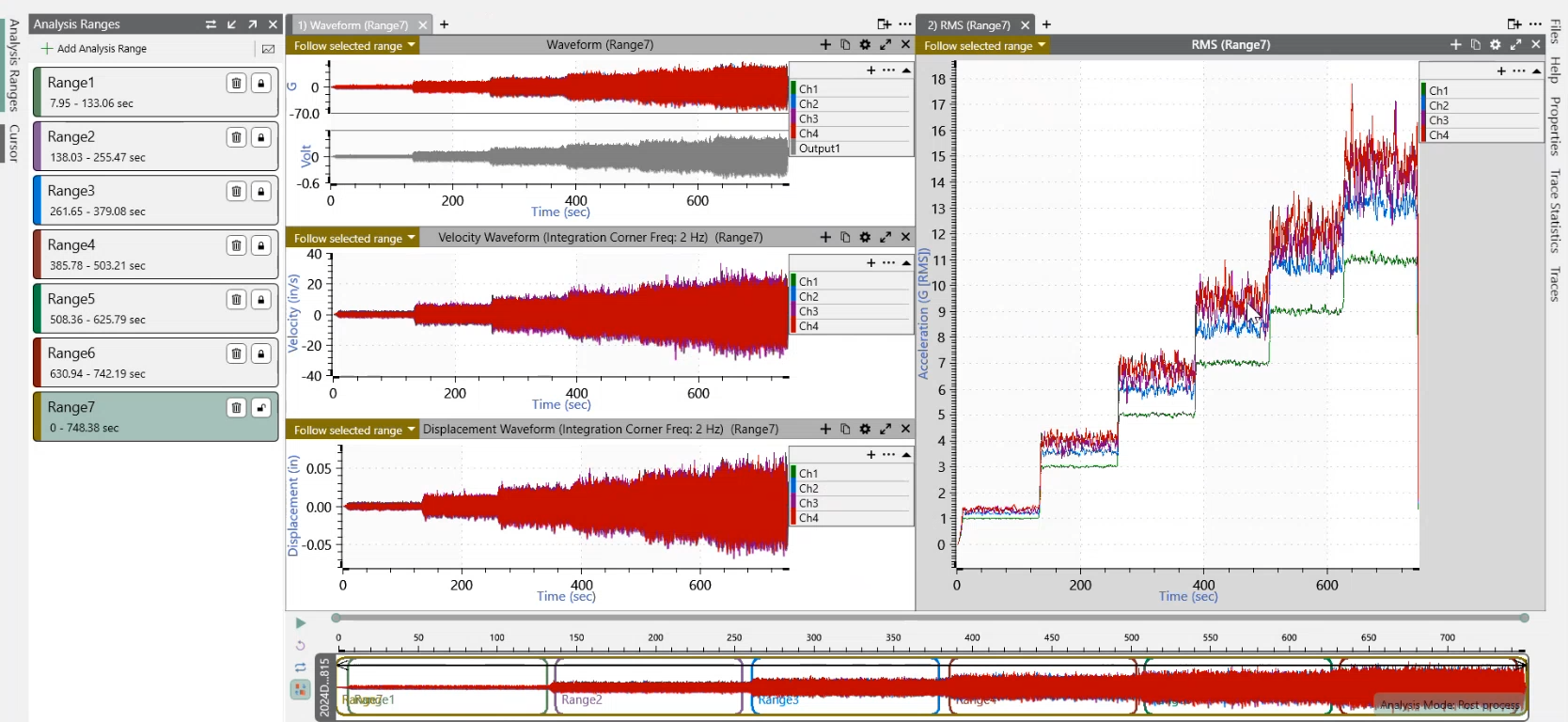

Engineers do not always analyze live vibration data during a shaker test. In many cases, they wait until a test is complete before reviewing the recordings—those from the test or an independent recording device.

Broadly, there are two aspects to post-test review of recorded shaker test data: test validity and product (DUT) insight. This step complements live monitoring by allowing engineers to correlate functional changes, response trends, and vibration levels over the entire test duration. It often reveals patterns that were not obvious during live monitoring.

For qualification, acceptance, or compliance testing, post-process analysis is often the primary method to confirm test pass/failure. It is also where engineers determine when and how a DUT began to degrade or fail, even if the test technically met all control requirements.

Confirming Test Completion & Consistency

After testing, engineers review raw recordings to verify that the test:

- Ran for the required duration

- Maintained the intended control levels

- Remained stable throughout execution with no intermittent failures

This process typically involves reviewing time histories, RMS trends, and frequency-domain representations such as PSDs. Engineers look for interruptions, dropouts, or unexpected changes that could invalidate the test.

Engineers may compare multiple runs or segments within a test to confirm that the vibration levels and spectral content remain uniform. Significant variation can indicate control instability, fixture changes, or instrumentation issues.

Intermittent failures that occur briefly during a vibration test may not be visible in final functional checks. Post-test review of recorded functional channels can reveal short-duration dropouts, timing errors, or transient events that occurred only under dynamic loading.

For many products, especially electronics, post-test analysis also includes a review of functional signals such as voltage, current, communication integrity, or sensor outputs recorded during vibration testing.

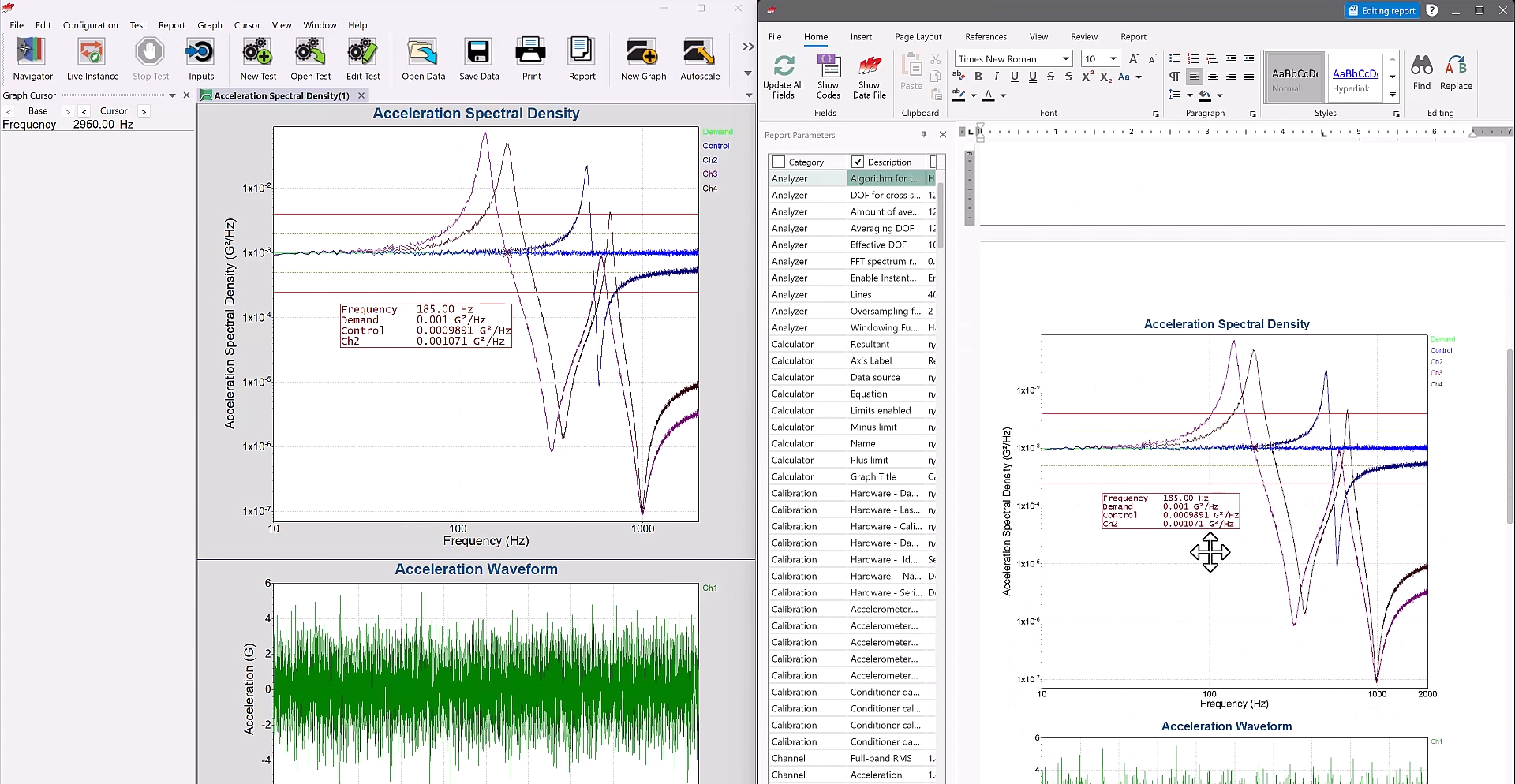

Identifying Deviations Between Test & Specification

Engineers also use post-test analysis to confirm compliance with a test specification. They can compare measured data to required limits, frequency bands, and tolerances defined in the test plan.

This comparison helps answer:

- Did the test meet all specified levels?

- Was there over-/under-testing at any frequencies?

- Did control or response deviate from allowable limits?

By identifying deviations post-test, engineers can determine whether the test is acceptable, needs to be repeated, or requires justification and documentation. It could also indicate when the DUT started to fail if resonance tracking was employed.

Creating Summary Reports & Documentation

After analysis, engineers typically generate summary reports for internal records or client documentation. These summaries may include:

- Confirmation of test completion

- Evidence of compliance with specifications

- Key plots (time histories, PSDs, trends)

- Notes on anomalies or deviations, if any

Clear documentation provides traceability, supports audits, and gives clients confidence that testing was performed correctly and evaluated with standard practices.

Post-test review is also a validation step against the pre-defined DFMEA. Engineers can use the results to confirm if any failure modes associated with vibration were observed, partially observed, or trending toward failure during the test. They may adjust the DFMEA or document lessons learned for future DFMEAs.

Conclusion

Beyond verifying test execution and compliance, engineers use post-test review to evaluate DUT behavior throughout vibration exposure. Engineers may analyze functional channels, response trends, or changes in transmissibility to determine when degradation began and how it progressed. When aligned with the DFMEA, post-test data helps distinguish between sudden failures, gradual wear-out, and intermittent behavior that may not be apparent during final functional checks.